Bayblend® FR3008 | (PC+ABS) FR(40) | Covestro Deutschland AG

Product Texts

(PC+ABS) blend

flame-retardant

improved chemical and hydrolysis resistance

HDT/A >= 85 °C

Vicat/B 120 = 103 °C

UL recognition 94 V-0 (1.5 mm)

glow wire test (GWFI): 960 °C (2.0 mm)

good light stability.

| Rheological properties | Value | Unit | Test Standard |

| Melt volume-flow rate, MVR | 13 | cm3/10min | ISO 1133 |

| Temperature | 240 | °C | ISO 1133 |

| Load | 5 | kg | ISO 1133 |

| Mechanical properties | Value | Unit | Test Standard |

| Tensile Modulus | 2800 | MPa | ISO 527-1/-2 |

| Yield stress | 60 | MPa | ISO 527-1/-2 |

| Yield strain | 4 | % | ISO 527-1/-2 |

| Thermal properties | Value | Unit | Test Standard |

| Temp. of deflection under load, 1.80 MPa | 85 | °C | ISO 75-1/-2 |

| Temp. of deflection under load, 0.45 MPa | 95 | °C | ISO 75-1/-2 |

| Vicat softening temperature, 50°C/h 50N | 101 | °C | ISO 306 |

| Coeff. of linear therm. expansion, parallel | 76 | E-6/K | ISO 11359-1/-2 |

| Coeff. of linear therm. expansion, normal | 80 | E-6/K | ISO 11359-1/-2 |

| Burning Behav. at 1.5 mm nom. thickn. | V-0 | class | IEC 60695-11-10 |

| Thickness tested (1.5) | 1.5 | mm | IEC 60695-11-10 |

| Yellow Card available | Yes | - | - |

| Burning Behav. 5V at thickness h | 5VB | class | IEC 60695-11-20 |

| Thickness tested | 2.0 | mm | IEC 60695-11-20 |

| Yellow Card available | Yes | - | - |

| Oxygen index | 32 | % | ISO 4589-1/-2 |

| Electrical properties | Value | Unit | Test Standard |

| Relative permittivity, 100Hz | 3.2 | - | IEC 60250 |

| Relative permittivity, 1MHz | 3.1 | - | IEC 60250 |

| Dissipation factor, 100Hz | 50 | E-4 | IEC 60250 |

| Dissipation factor, 1MHz | 70 | E-4 | IEC 60250 |

| Volume resistivity | >1E13 | Ohm*m | IEC 60093 |

| Surface resistivity | >1E15 | Ohm | IEC 60093 |

| Electric strength | 30 | kV/mm | IEC 60243-1 |

| Comparative tracking index | 300 | - | IEC 60112 |

| Other properties | Value | Unit | Test Standard |

| Water absorption | 0.5 | % | Sim. to ISO 62 |

| Humidity absorption | 0.2 | % | Sim. to ISO 62 |

| Density | 1180 | kg/m3 | ISO 1183 |

| Rheological calculation properties | Value | Unit | Test Standard |

| Density of melt | 980 | kg/m3 | - |

| Thermal conductivity of melt | 0.172 | W/(m K) | - |

| Spec. heat capacity melt | 2010 | J/(kg K) | - |

| Eff. thermal diffusivity | 8.73E-8 | m2/s | - |

| Ejection temperature | 100 | °C | - |

| Test specimen production | Value | Unit | Test Standard |

| Injection Molding, melt temperature | 240 | °C | ISO 294 |

| Injection Molding, mold temperature | 80 | °C | ISO 10724 |

| Injection Molding, injection velocity | 240 | mm/s | ISO 294 |

Characteristics

Processing

Injection Molding

Delivery form

Pellets

Additives

Release agent

Regional Availability

North America, Europe, Asia Pacific, South and Central America, Near East/Africa

Other text information

Injection molding

PREPROCESSING

Max. Water content: 0.02 %

Drying temperature: 75 - 100 °C

(depending on the grade 10°C below the Vicat VST/B120 temperature, but not higher as the recommended values).

Drying time:

Circulating air drying oven (50 % fresh air) 4-8 h

Fresh air dryer (high speed dryer) 2-4 h

Dry air dryer 2-4 h

PROCESSING

Melt temperature: 240-280 °C

Mold temperature: 70-100 °C

Use open nozzle.

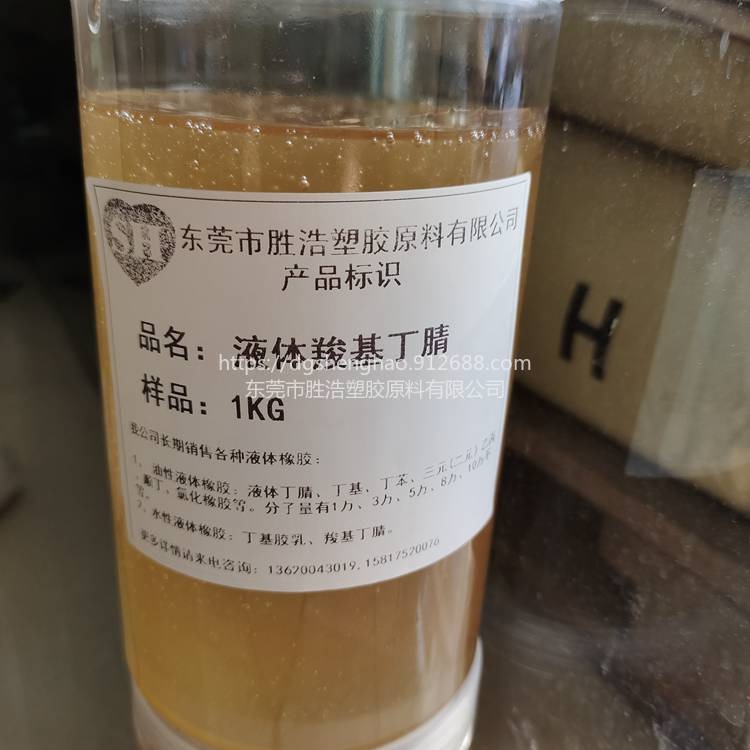

温馨提示您:

因本页面展示有限无法完全描述产品更多相关信息;塑胶原料行情每天每时波动较大无法及时更新,请亲们理解!

产品信息和 新价格请您及时来电!

- 东莞市胜浩塑胶原料有限公司

- 叶庚胜 销售部

- 13620043019

- 广东省东莞市樟木头镇塑胶商务中心7栋56号

为您精选

- 韩国LGPC/ABS HR5007A 合金LupoyHR5007A PC/ABS耐热 注塑级

- CYCOLOY-PC/ABS CX7240U SABIC 沙伯基础CX7240U PC/ABS抗紫外线阻燃V0

- 耐热PC/ABS HR5007AN LUPOY 韩国LGHR5007AN PC/ABS合金料

- PC/ABS无卤阻燃V0级 PC合金ABS 沙伯基础 防火 PC/ABS阻燃UL94V0

- PC/ABS阻燃ULV0级 沙伯基础C2800 CYCOLOY PC/ABSC2800防火5VB

- CYCOLOY PC/ABS C4210HF SABIC 沙伯基础C4210HF 玻纤10%增强

- PC/ABS无卤阻燃UL94V0 CYCOLOY沙伯基础C2950 防火PC/ABSC2950-111

- CYCOLOY PC/ABS HC1104HF SABIC沙伯基础HC1104HF 耐热 耐冲击

- CYCOLOY合金料PC/ABS C6200 SABIC沙伯基础C6200 PC/ABS无卤阻燃V0

- PC/ABS阻燃ULV0 沙伯基础CY6310 高流动PC/ABSCY6310 阻燃制品应用

- PC/ABS无卤阻燃V0 沙伯基础CY6025 CYCOLOY合金料PC/ABS CY6025 防火ULV0

- CYCOLOY沙伯基础MC1300 电镀级PC/ABS MC1300 注塑成型