品牌 : |

司太立 |

型号 : |

Ni60 |

焊粉成份 : |

镍基 |

加工定制 : |

是 |

牌号 : |

Ni60 |

熔点 : |

1050℃ |

适用范围 : |

适用于修复玻璃、塑料、橡胶等模 |

工作温度 : |

800 |

规格 : |

40-80 |

合金组份 : |

Ni W Co |

颗粒度 : |

40-80 |

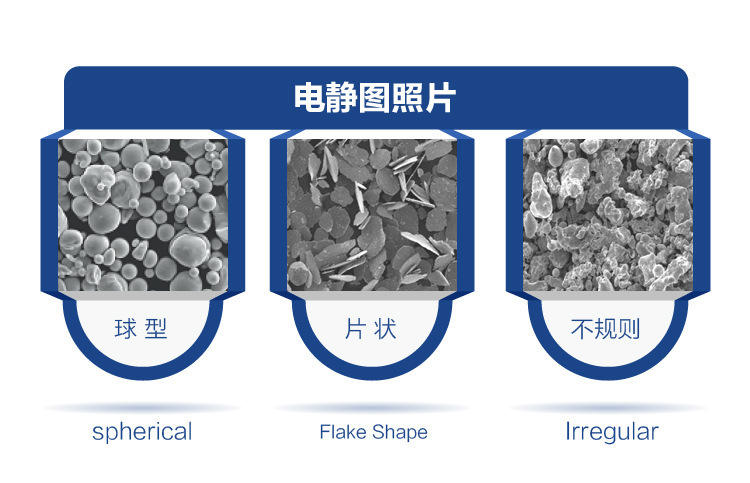

Ni60镍基自熔性合金粉末

产品特性:Ni60是高硬度的一种合金粉末,粉末的自熔性、润湿性和喷焊性能好、耐磨、耐蚀、切削困难适用于湿式磨削。

用途:适用于气门、阀门、柱塞、密封环、输送辊、泵套、刮板 ,油田采油机械,抽油杆极其接箍,平板阀板以及机筒内腔的离心浇注等。适用于喷焊,真空熔烧,堆焊等方法

粉末熔融温度:950~1050°C

喷焊沉积层硬度:HRC:58~63

粉末粒度范围:-150~+320目(二步法)-150- +400目(一步法)

粉末化学成份:

牌 号 | 化 学 成 份( %) | |||||||

C

| Si

| B

| Cr

| Cu | Mo | Fe

| Ni

| |

Ni60A | 0.7-1.0 | 3.5-5.5 | 3.0-4.5 | 15-18 | ≤5.0 | 余 量 | ||

Ni60 | 0.7-1.0 | 3.5-5.5 | 3.0-4.5 | 15-18 | ≤17 | |||

Ni60B | 0.7-1.0 | 3.5-5.5 | 3.0-4.5 | 15-18 | 2-4 | 2-4 | ≤5 | |

喷焊合金粉末,通称自熔性合金,亦称硬面合金。镍基喷焊合金粉末主要包括Ni-Cr-B-Si系列;Ni-Cr-B-Si-C系列;Ni-Cr-B-Si-C-Mo-Cu系列等,它具有优良的综合性能,耐腐蚀、抗氧化、耐热耐低应力磨粒磨损和粘着磨损等,具有优异的喷焊工艺性。

下而介绍我公司生产的镍基喷焊合金粉末均采用塑料桶和铁桶封装但由于粉末粒度细,易于吸潮,建议用户在使用前采用120℃保温两小时低温烘烤后使用。

Sprayed welding alloy powder is generally called as fluxed alloy or hard surface alloy. Nickel-base sprayed welding alloy powder mainly include Ni-Cr-B-Si serial products;Ni-Cr-B-Si-C serial products;Ni-Cr-B-Si-C-Mo-Cu serial products.The products have integrated performances. They are antirust, anti-oxidation, heat-resistant, with low stress abrasive particle wear resistance or adhesive wear resistance and has excellent technical performance for sprayed welding.

The following nikel-base sprayed welding alloy powder produced by our company is packaged and sealed in the plastic or metal pail. However, for the thin granularity and humidity-absorbing characteristic of the product, wesuggest that the customer dry the products under 120℃ for two hours before use.

- 南宫市海泰合金焊接材料厂

- 王先生 销售部

- 13473084955

- 河北省邢台市东进大街86号

为您精选